Intelligent Control

The centralized feeding system and key equipment are intelligently controlled to prevent human error and respond quickly.

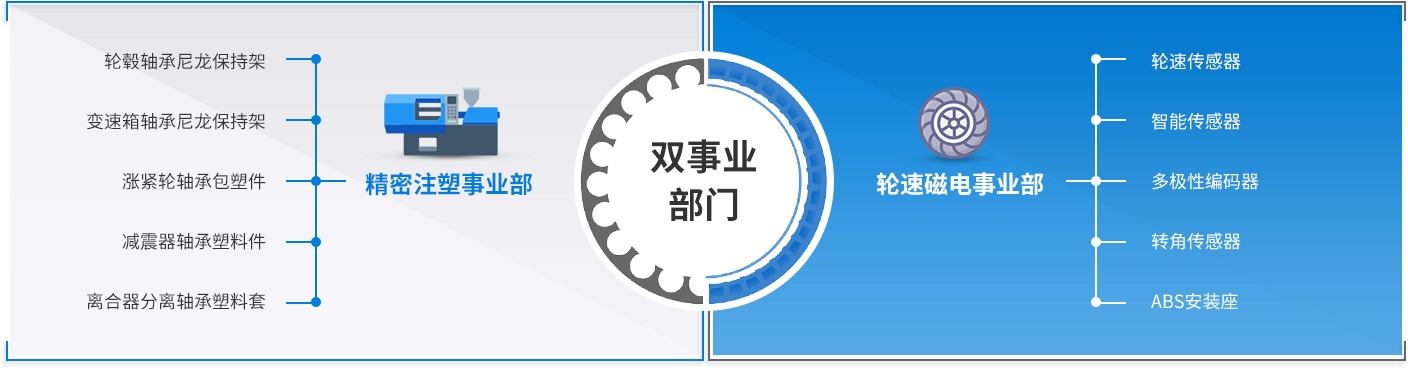

Zhejiang Kexiang and Zhejiang Chuangbo has been deeply engaged in the manufacture of plastic cages for automobile bearings for 20 years

Specializing in R&D and production of precision injection molded parts and sensors for automobiles

ZZhejiang Chuangbo Auto Parts Technology Co.,Ltd and Zhejiang Kexiang Auto Accessories Technology Co.,Ltd are located in Haining, a beautiful city with "the world's tide-viewing resort" and "China's leather capital". The Shanghai-Hangzhou-Ningbo Expressway runs through the urban area. It is 20 kilometers away from Hangzhou in the west and Shanghai in the east, with a very advantageous geographical location.

The company's own factory building area is 41,800M2, with more than 70 full CNC injection molding machines, ranging from 60 to 400 tons, equipped with Haitian high-end injection molding machines, Zhafir electric injection molding machines, Japan Sumitomo electric injection molding machines and FCS two-color machines, etc. The whole workshop realizes digital control and centralized water supply. In addition, for multi-process injection molding products, the company can customize special automation equipment to improve production efficiency and product accuracy. And we rationally use automation equipment to increase the production rate and effectively improve the quality control of the production process.

In the new voyage of 10,000 miles, Kexiang-Chuangbo will continue to build on the past, further improve the management level, research and development capabilities and product quality of the enterprise, and provide better products and services for the society. We will cooperate with you with the highest quality, best price and fastest delivery time for mutual benefit and common development. The chairman and team of Kexiang Chuangbo sincerely welcome new and old customers at home and abroad to come to our company, negotiate, cooperate and develop the future together!

Our company has always been at the forefront of science and technology, and strives to build a modern, intelligent and information-based factory that keeps pace with the times. Under the long-term development, the company has an excellent team, advanced equipment and perfect management system, which further strengthens the competitiveness of the enterprise.

The centralized feeding system and key equipment are intelligently controlled to prevent human error and respond quickly.

Technological innovation, inheritance of skills.

Improve efficiency and keep pace with the times.

Use system management software to achieve full traceability from raw materials to finished products. And keep the production date, production equipment and operator information of each batch of products for verification.

The company has more than 70 sets of national advanced injection molding equipment and system injection molding machines with tonnage ranging from 60 tons to 400 tons.

Mainly Haitian high-end injection molding machines.

The company uses FCS two-color machine, the repeatability of high precision, low pressure and low flow range is ±0.5%, and the weight deviation of molded products is controlled by 0.4%-0.7%, which is close to the level of semi-closed loop control; Process product requirements.

The company also has Sumitomo electric injection molding machines to provide customers with more efficient and precise product production. The whole workshop realizes centralized supply and water supply to keep the production site clean and efficient. And rational use of automation equipment to improve production rate.

The sensor department is equipped with multiple production lines, which produce various sensor wire harnesses and smart cover sensors for different types and clients. And equipped with a variety of imported automation equipment, such as Japan imported automatic winding machine, automatic wire cutting machine, automatic resistance welding machine and other automatic production equipment, as well as various process testing equipment. According to the product process and customer requirements, flexible production lines can be flexibly developed.